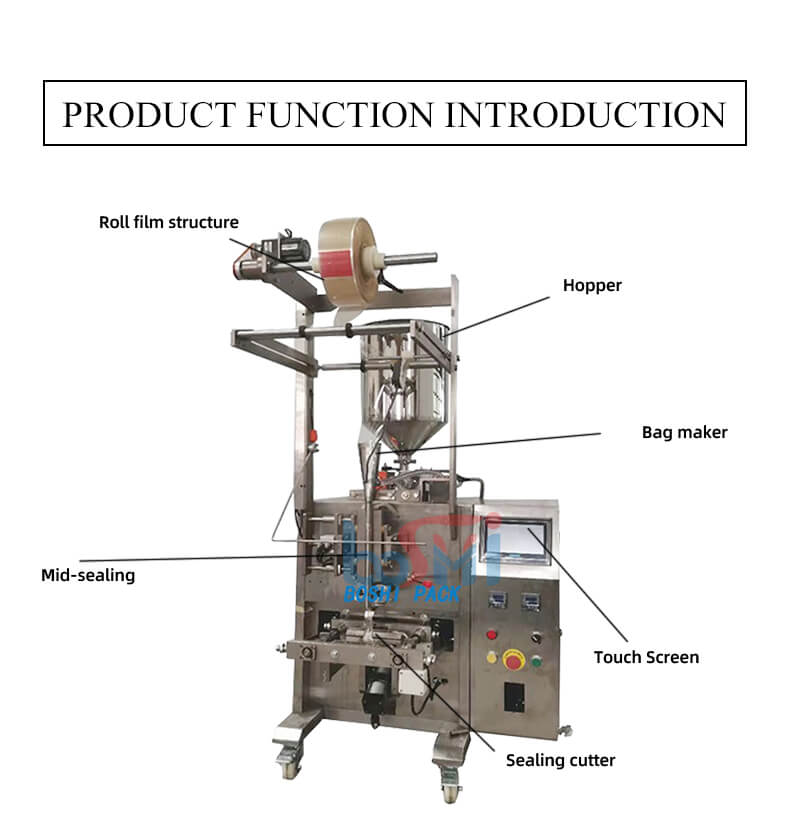

Boshi pack automatic sauce oil honey liquid packing machines

1)Material contact part is made of 316 stainless steel. Equipped with Airtac cylinder, high filling precision

2) Famous brands configurations, high work efficiency, works stable.

3) CE certifications, ISO, Google partner, Alibaba partner.

4)Safety protection and alarm function that effectively prevents incorrect packaging.

5)Adjustment of bag deviation just needed to be controlled by the touch screen.

6)All control is realized through software, easy for function adjusting and technical upgraded.

Boshi pack automatic sauce oil honey liquid packing machines

Product advantage:

1. The machine is controlled by double SCM (single chip) system and a LCD in English display.

2. The clear man-machine interface is easy to understand. All operation by press keys for: temperature setting,

length setting, counting setting, photo control, heating, mixing, move, run, stop.

3. Special and particular intelligence protection take the machine to auto stop to get the protection and display

the fail information when the machine fail in temperature control, color mark hunt control and film finish.

4. Two temperature controller to control the sealing temperature.

5. The bag length is controlled by electronic photo switch. The bag length will be cut accurately.

When the photo errs, the machine will stop and display “photo errs”.

6. When the packaging film is empty or broken, the machine will stop and display “film end”.

7. The intelligent counter: you can set the counter to a data you need, the machine will stop and

take alarm when reach the data you set. 8. The working is stable, easy to use, high yield and low wastage.

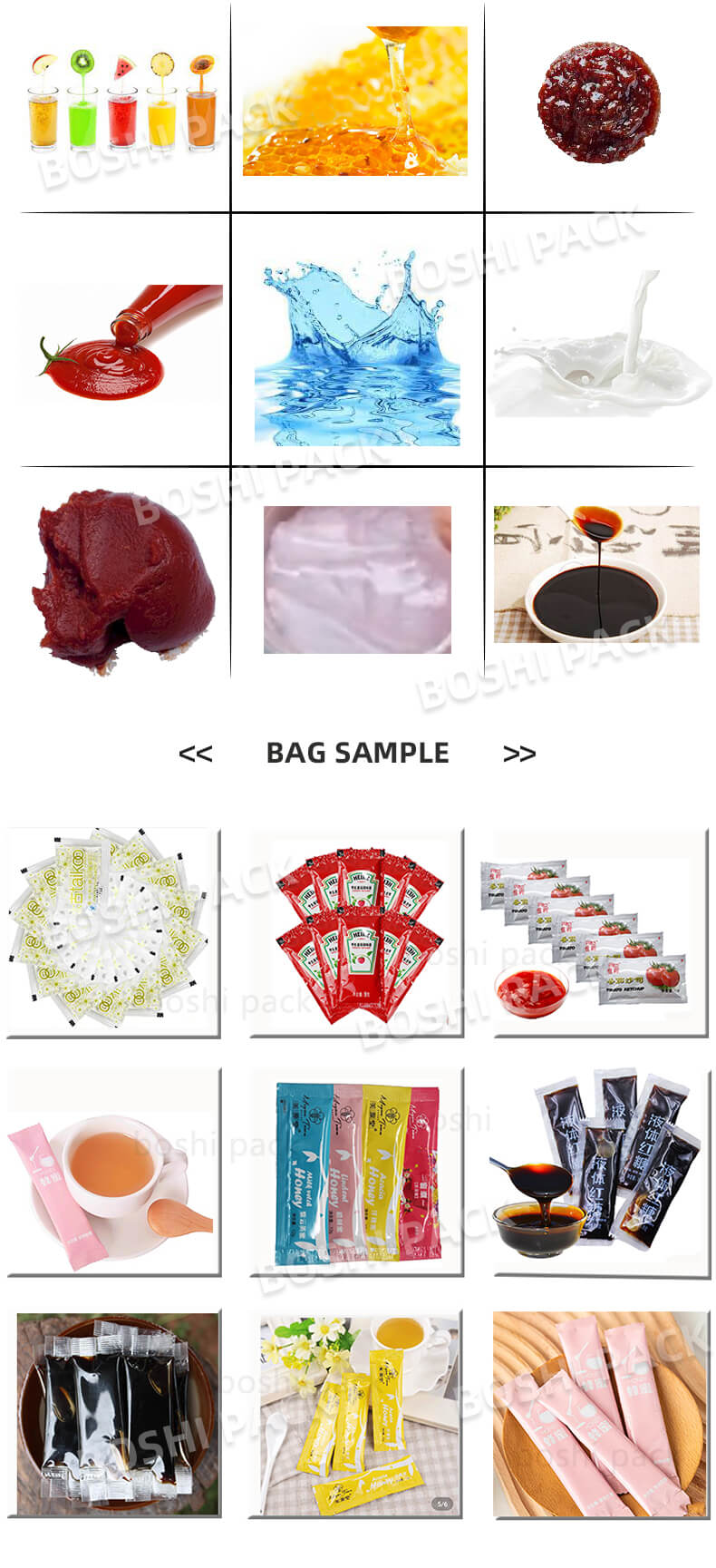

Product Applications:

It is widely to applied to packing liquid and paste products,

such as softener, shampoo, shower gel, milk, water, juice,

soybean sauce, oil, honey,jam,ketchup, mayonnaise and so on.

| Model | BS-240 |

| Filling range | 1-100 ml |

| Film width | Max.240mm |

| Film thickness | 0.03-0.1mm |

| Bag width | 15-110 mm |

| Bag length | 20-160mm |

| Sealing way | pillow bag, three sides seal bag, four sides seal bag |

| Packing speed | 45-70 bags/ min |

| Power | 1.2 KW |

| Machine weight | 165 kg |

| Dimensions | 600(L)* 600(W)1600(H) mm |

| Packing film materials | OPP, CPP, OPP/PE, PET/ PE, Aluminum, and etc. |