Multi lane 4 side seal back seal sachet drink mixed powder packaging machine vertical powder packing and sealing machine

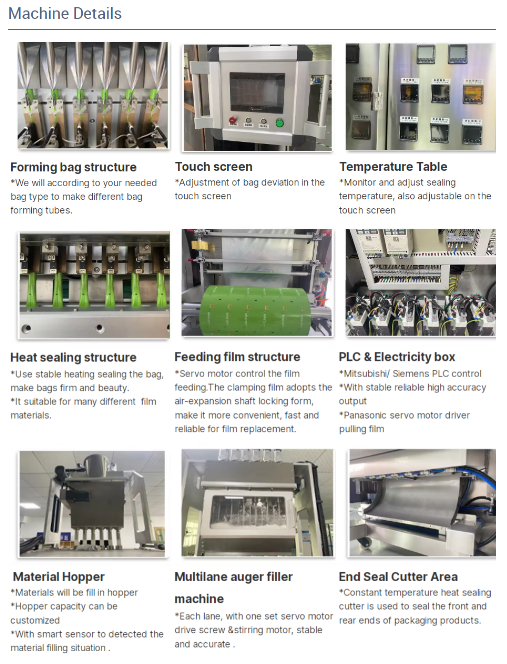

2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

3) High pressure double crank to control the die opening and closing.

4) Running in a high automatization and intellectualization,no pollution

5) Apply a linker to connect with the air conveyor ,which can directly inline with filling machine.

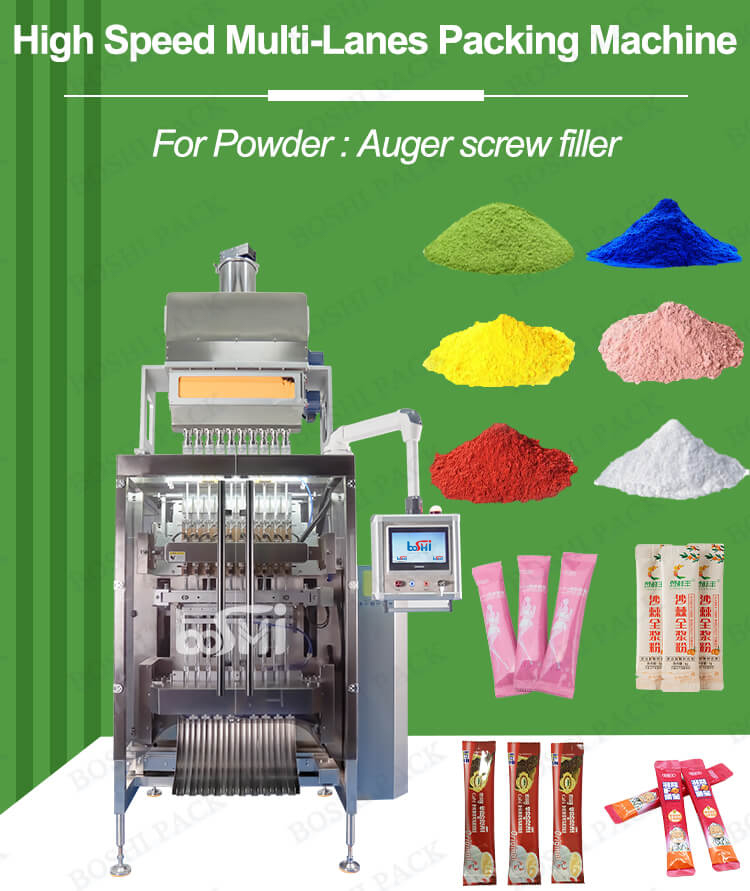

Multilane Powder Stick Pack Packaging Machine

1. PLC control with stable reliable biaxial high accuracy output and color touch screen, bag-making, measuring, filling, printing, cutting, finished in one operation.

2. Separate circuit boxes for pneumatic control and power control. Noise is low, and the circuit is more stable.

3. Film-pulling with servo motor double belt: less pulling resistance, bag is formed in good shape with better appearance, belt is resistant to be worn-out.

4. External film releasing mechanism: simpler and easier installation of packing film.

5. Adjustment of bag deviation just needed to be controlled by the touch screen. Operation is very simple.

6. Close down type mechanism , defending powder into inside of machine.

Suitable for filling and packing varieties of products:This type of machine can make pillow bag and then finish the packing process. The main packager can be integrated with various filling systems, suitable for all kinds of products, such as powder, small granule, liquid, viscous liquid, paste,tablet, candy, solid, stick, large solid and irregular products.

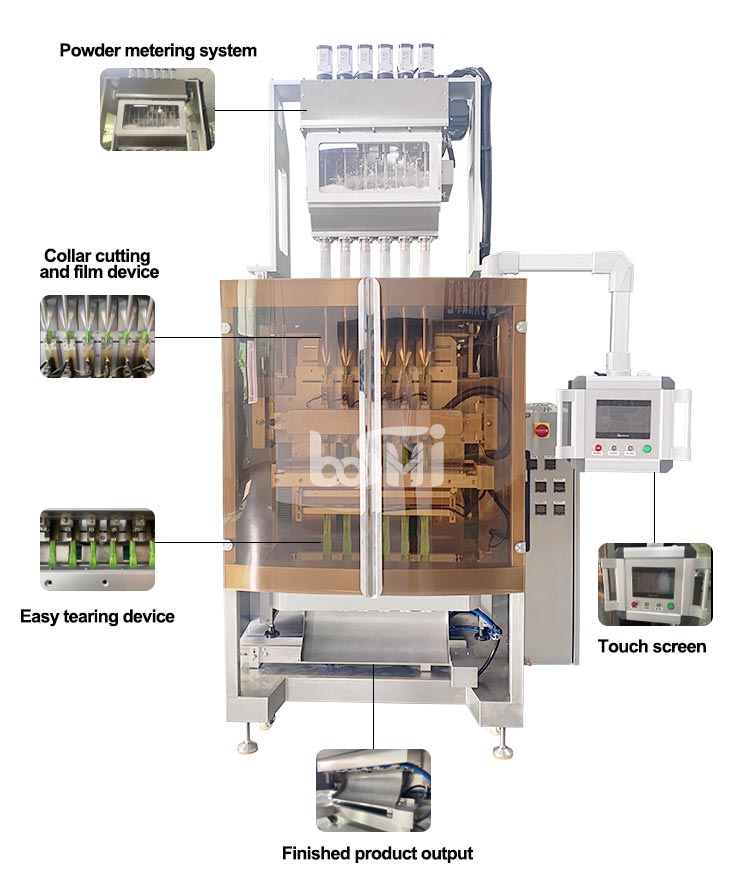

1. Injection of powder to be packed

2. Transport plastic film

3. Print date

4. Bag making and powder filling

5.Complete packaging, cutting and conveying finished products

|

Model |

BS-300BF |

BS-600BF |

BS-900BF |

|

Number of Lanes |

2-4 Lanes |

3-10 Lanes |

4-16 Lanes |

|

packaging speed |

20--40 cuts per minute/each lane |

||

|

Bag size |

L:50-180mm W:20-70mm |

L::50-180mm W:20-95mm |

Max.900mm,0.07--0.1mm |

|

Film width film thickness |

Max.300mm,0.07--0.1mm |

Max.600mm,0.07--0.1mm |

Max.900mm,0.07--0.1mm |

|

Measurement method |

1. Long screw; 2. Short screw; 3. Short screw + material rejection |

||

|

Sealing bag type |

Pillow bag, 3 side seal bag, 4 side seal bag, special shape bag |

||

|

Incision form |

1. Flat cutting; 2. wave cutting; 3. Rounded cutting; 4. Special-shaped cutting |

||

|

Power supply |

1N+PE/50HZ/AC220V/380V/3.5kw |

1N+PE/50HZ/AC220V/380V/5.5kw |

1N+PE/50HZ/AC220V/380V/7.5kw |

|

Air consumption |

0.8 MPA 0.8m3/min |

0.8 MPA 0.8m3/min |

0.8 MPA 0.8m3/min |

|

Machine dimension |

1385*918*2005mm |

1685*1300*2005mm |

1700*1600*2500mm |

|

Machine weight |

400kg |

600kg |

950kg |